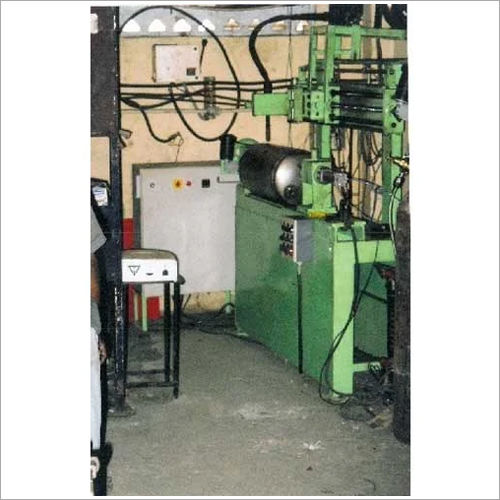

Pull Through H Beam Welding Automation Systems PTW Beam welder

Product Details:

Pull Through H Beam Welding Automation Systems PTW Beam welder Price And Quantity

- 1 Piece

Pull Through H Beam Welding Automation Systems PTW Beam welder Trade Information

- 2 - 3 Piece Per Month

- 15 Days

- All India

Product Description

Weldinghead)usedtoassembleandweld Hbeam.ComparedwithNormalvertical line, it has the advantages of higher productivityand less deformation, and is suitable forproducing PEB H beams.Noneedofflangestraighteningmachine.

WorkingProcess:-

Put one piece of Web plate to middleof roller put two pieces of Flangeplateto bothsidesofrollerrollerconveysWebandFlangeplatestoVerticalSweepCorrection Flangetiltingdevicemakesflangesvertically tiltdevicereset Weblifting deviceraises web plate to right position align end of three plates manualtack welding of leading edge end Weblifting device falls roller conveys workpieceto Pull through welding machine (PTW) flange clamp device of PTW welderclampstheflangeplates weblifterofPTWwelderadjustswebheight sidepressdevice of PTW welder presses H beam flange plate web press device ofPTWwelder presses the web plate adjust position of welding torch start flux feederswitch startfluxrecoveryswitch startwelding stopwelding cutfluxfeederswitchcutfluxrecoveryswitch

Sophisticated Welding Automation for Industry

The PTW Beam Welder elevates beam fabrication processes by automating welding tasks. With an electric motor and intuitive controls, operators can efficiently manage complex welding operations, minimizing downtime and maximizing throughput. Its robust design ensures reliable performance even in demanding industrial environments.

Ideal Solution for Indian Fabricators

Exclusively tailored for the needs of Indian manufacturers, suppliers, and traders, this system meets local and international standards. The automation technology optimizes the use of resources and helps fabricators quickly adapt to evolving market demands while maintaining high welding quality.

Efficiency and Quality Unleashed

The Pull Through H Beam Welding Automation System combines speed with accuracy, producing consistent welds and greatly reducing human intervention. This results in superior product quality, faster cycle times, and reduced production costs across a wide spectrum of industrial applications.

FAQs of Pull Through H Beam Welding Automation Systems PTW Beam welder:

Q: How does the Pull Through H Beam Welding Automation System enhance industrial welding operations?

A: This system automates the welding process for H beams, ensuring uniform welds and reducing human error. It increases production speed, consistency, and overall efficiency, making it especially beneficial for high-volume industrial fabrication.Q: What is the process involved in operating the PTW Beam Welder?

A: Operators load the H beams onto the system, set the required welding parameters, and activate the machine. The electric motor and automated controls guide the welding head along the beam, ensuring precise and consistent welds from start to finish.Q: Where can this welding automation system be used?

A: The PTW Beam Welder is designed for use in industrial settings such as steel fabrication plants, manufacturing units, and heavy engineering workshops, particularly in India where demand for large-scale structural welding is high.Q: When should a company consider investing in a PTW Beam Welding Automation System?

A: Companies should consider this system when aiming to boost production capacity, improve weld consistency, minimize manual labor, or modernize their fabrication processes for competitive advantage.Q: What are the main benefits of using a Pull Through H Beam Welding Automation System?

A: Key benefits include increased productivity, superior weld quality, reduced operational costs, and enhanced workplace safety. Automating the process also allows businesses to handle larger projects with fewer resources and less downtime.Q: How does the electric motor contribute to the systems performance?

A: The electric motor delivers reliable and controlled power to the automation system, enabling precise movement of the welding head. This consistency is vital for achieving high-quality welds and maintaining steady production rates.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry